WIRE

At MRT we are wire manufacturers

Celsa supplies the raw material for our wire (the wire rod). This allows MRT to offer traceability and product consistency, allowing for greater control over supply. The packaging of the wire is adapted to the needs and distance from our customers, we can offer the products palletized, wrapped in transparent film or even with integral packaging (exterior and interior).

With more than 150 years of experience, MRT manufactures a wide range of wires with coatings adapted to the needs of each sector and market.

Agriculture and hardware wire

It is wire packaged in small formats for uses such as: greenhouses, vineyards, do-it-yourself, construction, etc.

Wire for industry and transformation

Product intended for further processing, some examples of sectors for which it is intended are: manufacture of metal fasteners, hangers, handles, staples, electrical cable protection, packaging industry, nets and wire mesh, etc.

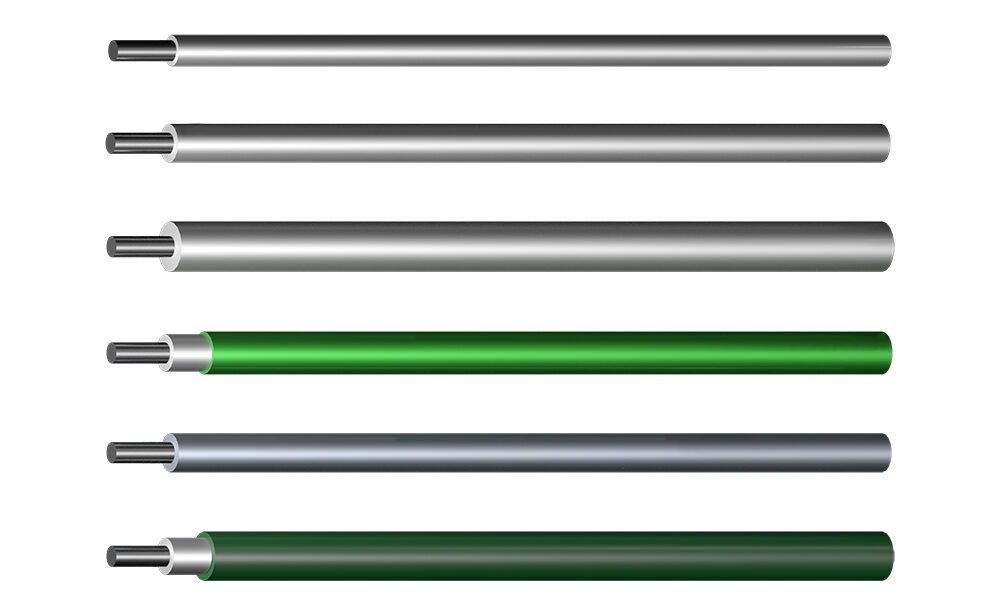

Our brands of coatings

Ecover

Ecover coating consists of adding a green metallic passivation based on chromium (Cr3+) and titanium (Ti) to heavy galvanized wire, with a thickness of approximately 1 to 3 µm.

Ecover gives the wire greater corrosion resistance (three times greater than heavy galvanized wire). It is an exclusive coating from MRT.

This low-friction coating facilitates the wire’s transformation into mesh or strands by forming.

- It offers a better integration with nature thanks to its green color.

- It includes a certificate of useful life.

- Its durability and high quality make it a good investment.

- MRT manufactures a wide range of products with Ecover.

ZnAl

The ZnAl alloy consists of 95% Zinc and 5% Aluminum. It is applied in the manufacture of wire (diameter from 1.40 mm to 4.50 mm) to increase its resistance to corrosion. There are three possible coating options Class A, B and AB. All three comply with EN 10244-2. Salt spray chamber tests have shown that ZnAl wire has a significantly slower corrosion rate compared to heavy galvanized wire (also in welded areas).

- The coating is more homogeneous and ductile, which allows excellent adhesion to the wire.

- Bright metallic surface.

- It does not flake easily.

- The ZnAl laminated structure adapts perfectly to the profiling, inlaying and folding processes.

What is ZnAl coating?

This video explains the characteristics of the MRT ZnAl coating, a zinc and aluminum alloy (95% zinc and 5% aluminum).

Thanks to ZnAl, the wire increases its useful life up to 3 times, if we compare it with reinforced galvanizing.